Digital Twin

Explore intuitive vibration diagnosis

Digital Twin

Explore intuitive vibration diagnosis

Intro

It’s all about Data-Driven Decision Making

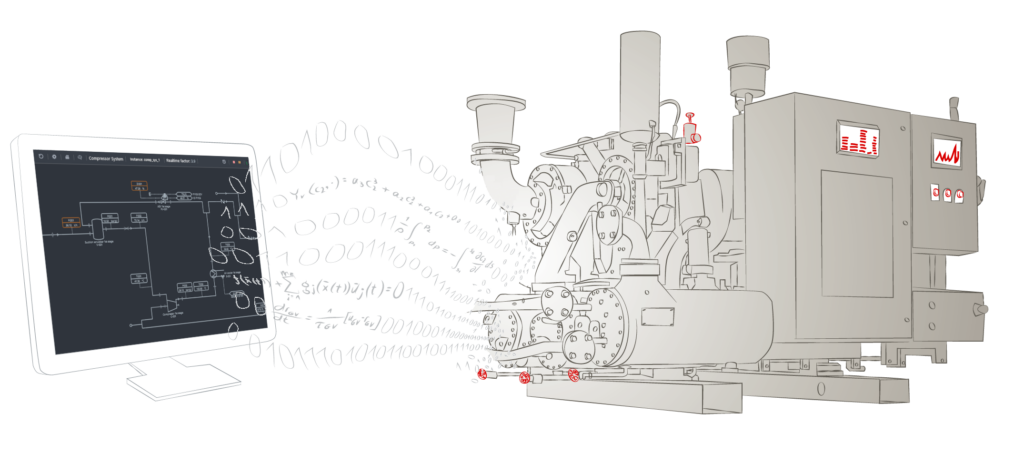

The industry faces challenges in optimizing production processes and achieving climate-neutrality while managing costs. Digital Twin technologies offer solutions to these challenges. The Digital Twin is a tool for enhancing availability and productivity, reducing maintenance and energy/environmental costs, and enabling informed decision-making based on operational data.

But what is the Digital Twin? For us, it’s a unique digital representation mirroring the physical object. Integrating all relevant data into a dynamic multi-domain model, it evolves throughout the plant lifecycle to remain an up-to-date counterpart. The combination of operational experience and our expertise in process engineering, instrumentation and control creates a synergy that unlocks amazing opportunities!

Services

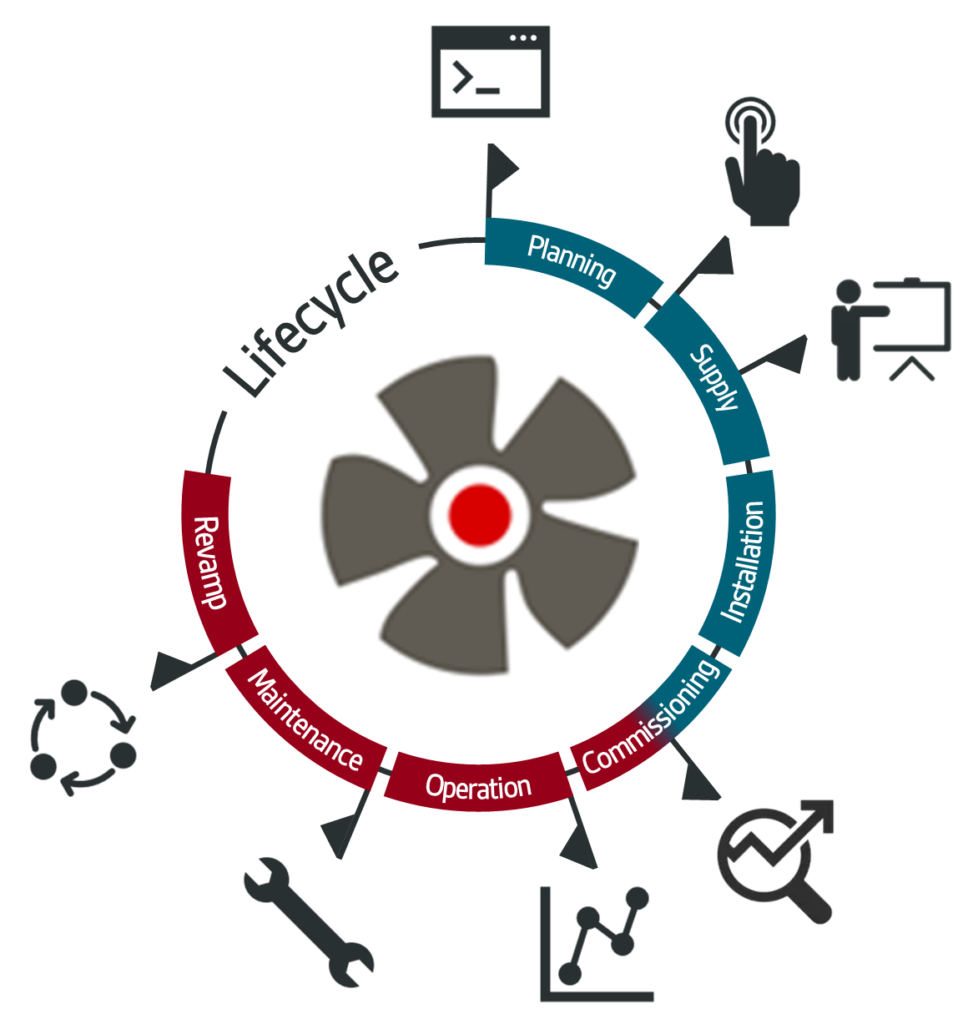

Following Plant’s Lifecycle

The Digital Twin supports decision-making throughout the entire plant lifecycle, from planning to modernization. It generates a highly accurate, dynamic process model using provided design and process data. Our simulation environment, equipped with powerful optimization algorithms, drives the evolution of the Digital Twin throughout its lifecycle. By merging design and field data, it provides a holistic view of the plant, offering valuable insights into its operation.

Use Cases

Explore amazing Opportunities

Integration

?????

Hardware Integration

Software Integration

Features

??????

Raw data – Save raw data snapshots using time- and event-based triggers including pre- and post-event data

Performing – Intelligent data management scheme for maximum data transfer performance and analysis speed

Analysis – Perform ad-hoc vibration analysis on every snapshot like FFT, Orbit, ISO10816

Purposeful – The Flight Recorder only records relevant machine events, ensuring that no unnecessary data is stored

Multi-Purpose – 6 galvanically isolated multi-purpose analog inputs for proximitors, keyphasors, transmitter & rack Buffered Out connectors as well as velocity, acceleration, speed & dynamic pressure sensors

Multi-Power – Each channel can be configured as 2-wire (IEPE 6mA), 3-wire (+24VDC / -24VDC supply) our without power supply.

Multi-Range – Measure sensor data in unipolar range 0 .. ±24V or bipolar range ±24V.

High Quality – 24bit time synchronous sampling @ 100kHz

Small Size – IP20 casing with DIN rail mounting, 45 x 120 x 120mm

Connected – 2x GbE RJ45

Industrial Range – From -20 to +65°C operating temperature @ 10 .. 90% humidity

Optimized – The Gateway ensures high data throughput, storing full-resolution data for around 2 years (typical use), with automatic data reduction at max database capacity.

Trusted – Our METIS software relies on an long-term supported industrial Linux OS from Siemens.

Small Size – Big performance, small footprint. Instead of using big server racks we are using robust IPCs: Small (85 x 85 x 41mm) or Large (191 x 100 x 60mm).

Small Gateway – Quad Atom E3940, 4 GB RAM, 64/128 GB SSD, 2x GbE RJ45, 1x DisplayPort, DIN rail mount

Large Gateway – Quad Celeron N2930, 8 GB RAM, 128/240/480 GB SSD, 2x GbE RJ45, 1x DisplayPort, DIN rail mount

Turbo compressor shaft vibration

Gearbox vibration

Reciprocating compressor vibration

Pump and fan vibration

Housing & bearing vibration

Machine-to-Machine – OPC UA, Modbus TCP, GE Historian Client

Manual Export – JSON, XLS/CSV, NI TDMS, Matlab® MAT

Direct Access – REST API

Expandable – Additional M2M and Export Connectors can be provided on request

Contact

Dr. Rico Schulze

Rico.Schulze@avicomp.com

+49 341 21787 1791

Kevin Schleifer

Kevin.Schleifer@avicomp.com

+49 341 21787 1784