CCM

Explore intuitive vibration diagnosis

CCM

Explore intuitive vibration diagnosis

Intro

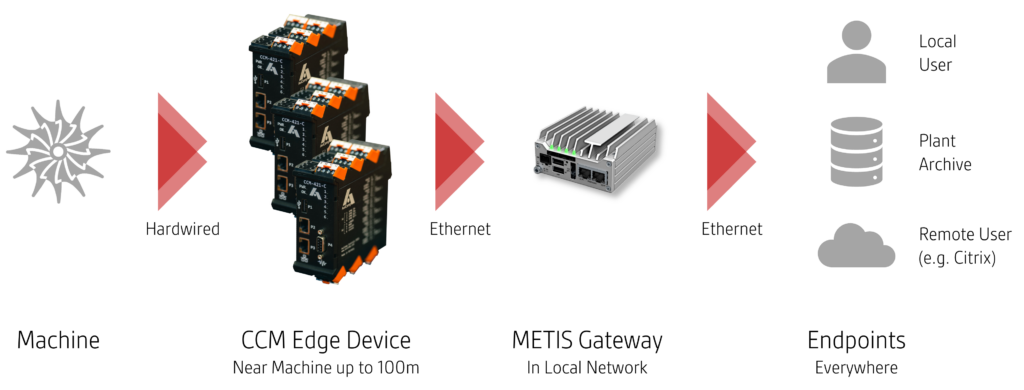

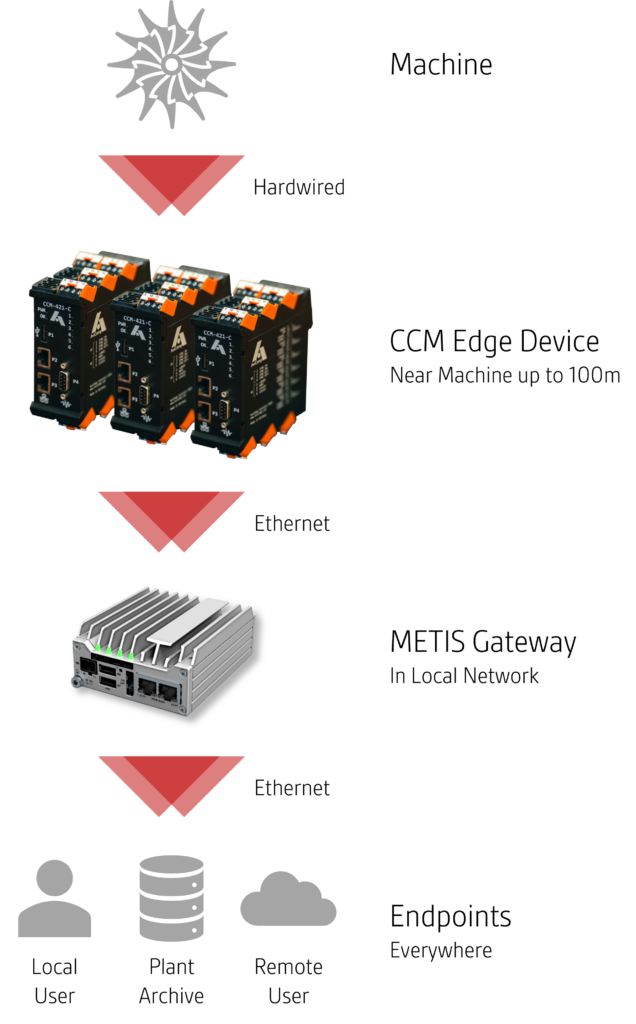

Open, scalable and easy to integrate

The CCM system is the backbone for reliable condition monitoring, machine diagnostics and early fault detection – from housing vibration to shaft vibration in rotating machinery. It sets new standards with its openness, scalability and ease of integration. By separating machine data acquisition from remote data processing, the system offers maximum flexibility and modularity.

The CCM system easily integrates with existing infrastructures, both software and physical. It provides accurate insight into machine status and supports data-driven decisions. The added value is reflected in reduced downtime due to improved maintenance planning, the avoidance of recurring faulty conditions and the reduction of wear and tear.

METIS

The solution for intuitive monitoring

METIS is a powerful software platform for processing, visualizing and networking vibration data. The web-based user interface provides comprehensive insight into time data, orbits, spectra, Nx filters and more. Intuitive operation and seamless extensibility are made possible by a consistent focus on user needs and an innovative software architecture.

METIS offers very fast configuration, decentralized data storage with backup functionality, and connectors for effective data transfer. The powerful flight recorder captures critical events in high resolution at up to 96 kHz. Combined with our CCM hardware, METIS is the ideal solution for continuous condition monitoring, predictive maintenance and optimization of machines and systems.

Services

Unique services for unique assets

Integration

Seamless integration with customized simplicity

Hardware Integration

Software Integration

Features

| Raw data | Save raw data snapshots using time- and event-based triggers including pre- and post-event data |

| Performing | Intelligent data management scheme for maximum data transfer performance and analysis speed |

| Analysis | Perform ad-hoc vibration analysis on every snapshot like FFT, Orbit, ISO10816 |

| Purposeful | The Flight Recorder only records relevant machine events, ensuring that no unnecessary data is stored |

| Multi-Purpose | 6 galvanically isolated multi-purpose analog inputs for proximitors, keyphasors, transmitter & rack Buffered Out connectors as well as velocity, acceleration, speed & dynamic pressure sensors |

| Multi-Power | Each channel can be configured as 2-wire (IEPE 6mA), 3-wire (+24VDC / -24VDC supply) our without power supply. |

| Multi-Range | Measure sensor data in unipolar range 0 .. ±24V or bipolar range ±24V. |

| High Quality | 24bit time synchronous sampling @ 100kHz |

| Small Size | IP20 casing with DIN rail mounting, 45 x 120 x 120mm |

| Connected | 2x GbE RJ45 |

| Industrial Range | From -20 to +65°C operating temperature @ 10 .. 90% humidity |

| Optimized | The Gateway ensures high data throughput, storing full-resolution data for around 2 years (typical use), with automatic data reduction at max database capacity. |

| Trusted | Our METIS software relies on an long-term supported industrial Linux OS from Siemens. |

| Small Size | Big performance, small footprint. Instead of using big server racks we are using robust IPCs: Small (85 x 85 x 41mm) or Large (191 x 100 x 60mm). |

| Small Gateway | Quad Atom E3940, 4 GB RAM, 64/128 GB SSD, 2x GbE RJ45, 1x DisplayPort, DIN rail mount |

| Large Gateway | Quad Celeron N2930, 8 GB RAM, 128/240/480 GB SSD, 2x GbE RJ45, 1x DisplayPort, DIN rail mount |

- Turbo compressor shaft vibration

- Gearbox vibration

- Reciprocating compressor vibration

- Pump and fan vibration

- Housing & bearing vibration

| Machine-to-Machine | OPC UA, Modbus TCP, GE Historian Client |

| Manual Export | JSON, XLS/CSV, NI TDMS, Matlab® MAT |

| Direct Access | REST API |

| Expandable | Additional M2M and Export Connectors can be provided on request |

Contact

Dr. Rico Schulze

Rico.Schulze@avicomp.com

+49 341 21787 1791