The right decision at the right time

The Digital Twin combines machine data and process parameters to create a realistic digital replica – for simulation, virtual commissioning and real time monitoring.

The Digital Twin provides more than data. It provides insight for well-founded decisions, reliable processes & deeper understanding across assets and plants

Gain confidence by virtually designing, testing and commissioning technical changes

Resolve troubles quickly and sustainably

Gain insight in asset performance and find potential for increasing availability and efficiency

Drive cost-effective maintenance strategies and modernization planning

Train operators with ultra-realistic process behavior

Explore amazing opportunities

We lay the foundation for condition-based maintenance, greater efficiency, and long-term operational reliability — through digital twins combined with in-depth process understanding and engineering expertise.

Virtual commissioning of an extraction turbine

Revamp of obsolete Woodward speed and Ascania extraction controller incl. valve actuators. The Digital Twin was used to test the new PLC-based controller in closed-loop. Therefore, the Digital Twin has been connected to the PLC in a real-time setup.

Compressor reverse rotation

A multi-stage turbine-driven air compressor experienced severe reverse rotation at 80% of rated speed during an emergency shutdown. The Digital Twin was used to reproduce the incident and to provide recommendations for the placement and sizing of additional blow-off valves and silencers.

Increasing energy efficiency

Using a digital twin to optimize a multi-stage ammonia compressor. Simulations revealed efficiency reserves, improved the control strategy, and reduced steam consumption.

Optimization of water pump station

To optimize energy consumption, a digital twin of three parallel, speed-controlled feed pumps was used. Different pump sizes and combinations have been analyzed. In addition, the control scheme has been optimized to minimize switching events. This ensures higher pressure stability and reduced wear.

Operator training of compressor control

The Digital Twin has been used to train upgraded anti-surge control of the cracked gas, ethylene and propylene compressors in an ethylene cracker plant. This builds trust in the control upgrade for operators and improvement team even before hot commissioning.

Drive informend decision-making

We think people make good decisions when they understand what’s going on.

For us, the Digital Twin means transparency, security, and clarity—especially when complexity becomes paralyzing. It makes the invisible visible and the complicated manageable, so that engineers, maintenance crew, operators, and decision-makers can act with calm and confidence.

Holistic – includes all relevant process components, consumer and control systems

Fully dynamical – understand effects of process dynamics like startup, shutdown, equipment failure

High fidelity – Digital Twin is trained with process data to capture all relevant operating modes

Connectable – Integrate the Digital Twin with your real asset or connect to other simulation systems

Independet since 20 years – 100% owened by us. 100% control for customer solutions

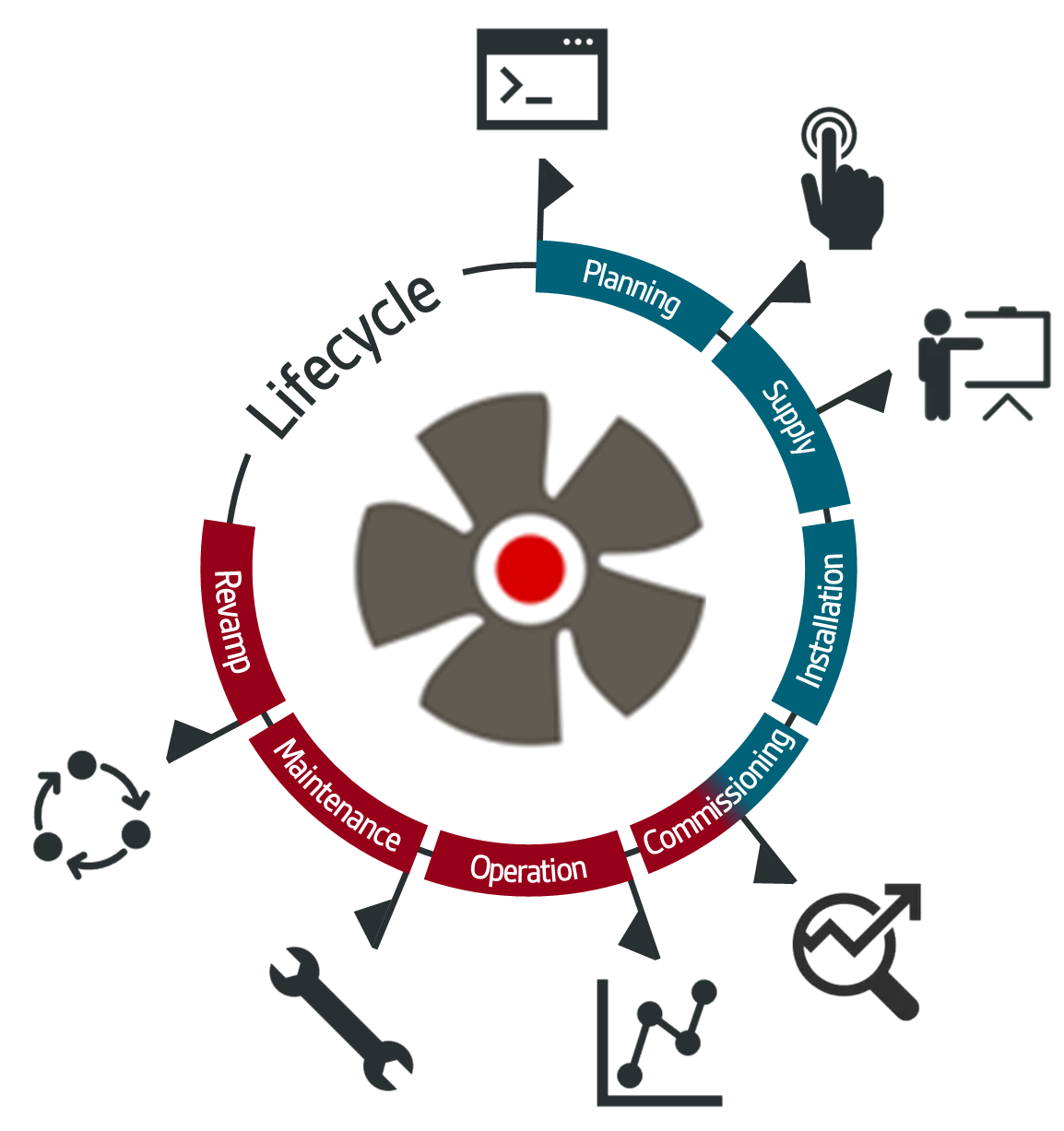

One Digital Twin following the lifecycle

Like to discover more or discuss a specific project?

Dr.-Ing. Rico Schulze

Head of Digital Solutions

| Phone: | +49 341 21787-1791 |

| Mobil: | +49 1525 6858222 |

| Email: | rico.schulze@avicomp.com |

| LinkedIn: | www.linkedin.com/in/dr-rico-schulze |